- Product Introduction

- Product principle

- Product picture

- Typical Case

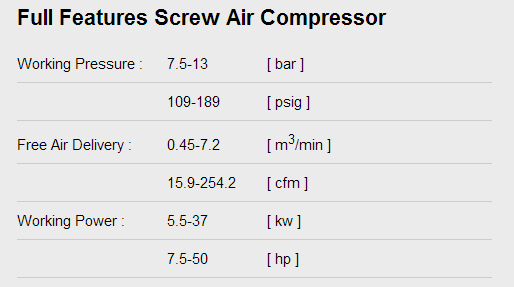

Full Features Screw Air Compressor

Product principle:

Full Features Screw Air Compressor Advantages:

DENAIR combined screw air compressor is assembled with rotary screw air compressor, air storage tank, refrigerant-type air dryer and air filters.

The air dryer and filters efficiently remove moisture, aerosols and dirt particles to protect your equipment. This high quality air expands the life of equipment, increases efficiency and ensures quality in your final product.

Easy to install, operate and move. And space-saving.

State-of-the-art screw element, original Germany DENAIR air end, advanced SAP profile design, superior Sweden SKF element bearings.

Adopts world-renowned components, such as Schneider electronics from France, Mann filters from Germany, Danfoss pressure sensor from Denmark, etc. contribute to guarantee the compressor longer service life.

Conform to CE, ISO9001 and energy saving certification, etc.

Product Introduction:

Product Picture:

Technical Parameters For EEI1:

Technical Parameters For EEI2:

Technical Parameters For EEI2:

| Model |

Maximum Working Pressure |

Capacity(FAD) |

Installed Motor Power |

DrivingMode & Cooling Method |

Dimensions(mm) | Weight | Noise level |

Air Tank Capacity |

Air Outlet Pipe Diamter |

EEI | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| bar | psig | m3/min | cfm | KW | hp | L | W | H | Kg | [dB(A)] | L | ||||

| DNA-15LG+ | 7.5 | 109 | 2.69 | 95.0 | 15 | 20 |

Direct Driven Air Cooing |

2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | EEI1 |

| 8.5 | 123 | 2.47 | 87.2 | 15 | 20 | 2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | |||

| 10.5 | 152 | 2.28 | 80.5 | 15 | 20 | 2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | |||

| 13 | 189 | 1.89 | 66.7 | 15 | 20 | 2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | |||

| DNA-18LG+ | 7.5 | 109 | 3.31 | 116.9 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | ||

| 8.5 | 123 | 3.20 | 113.0 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | |||

| 10.5 | 152 | 2.80 | 98.9 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | |||

| 13 | 189 | 2.40 | 84.70 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | |||

| DNA-22LG+ | 7.5 | 109 | 4.11 | 145.1 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | ||

| 8.5 | 123 | 3.71 | 131.0 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | |||

| 10.5 | 152 | 3.50 | 123.6 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | |||

| 13 | 189 | 3.40 | 120.1 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | |||

| DNA-30LG+ | 7.5 | 109 | 6.00 | 211.9 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | ||

| 8.5 | 123 | 5.71 | 201.6 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | |||

| 10.5 | 152 | 4.90 | 173.0 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | |||

| 13 | 189 | 4.00 | 141.2 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | |||

| DNA-37LG+ | 7.5 | 109 | 7.20 | 254.2 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | ||

| 8.5 | 123 | 6.97 | 246.1 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | |||

| 10.5 | 152 | 5.98 | 211.2 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | |||

| 13 | 189 | 5.05 | 178.3 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | |||

| Model |

Maximum Working Pressure |

Capacity(FAD) |

Installed Motor Power |

DrivingMode & Cooling Method |

Dimensions(mm) | Weight | Noise level |

Air Tank Capacity |

Air Outlet Pipe Diamter |

EEI | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| bar | psig | m3/min | cfm | KW | hp | L | W | H | Kg | [dB(A)] | L | ||||

| DNA-5LG | 7.5 | 109 | 0.86 | 30.4 | 5.5 | 7.5 |

Belt Drive Air Cooing |

1686 | 800 | 1285 | 450 | 62 | 200 | G3/4 | EEI2 |

| 8.5 | 123 | 0.79 | 27.9 | 5.5 | 7.5 | 1686 | 800 | 1285 | 450 | 62 | 200 | G3/4 | |||

| 10.5 | 152 | 0.65 | 23.0 | 5.5 | 7.5 | 1686 | 800 | 1285 | 450 | 62 | 200 | G3/4 | |||

| 13 | 189 | 0.45 | 15.9 | 5.5 | 7.5 | 1686 | 800 | 1285 | 450 | 62 | 200 | G3/4 | |||

| DNA-7LG | 7.5 | 109 | 1.19 | 42.0 | 7.5 | 10 | 1686 | 800 | 1285 | 475 | 62 | 200 | G3/4 | ||

| 8.5 | 123 | 1.08 | 38.1 | 7.5 | 10 | 1686 | 800 | 1285 | 475 | 62 | 200 | G3/4 | |||

| 10.5 | 152 | 0.95 | 33.5 | 7.5 | 10 | 1686 | 800 | 1285 | 475 | 62 | 200 | G3/4 | |||

| 13 | 189 | 0.70 | 24.7 | 7.5 | 10 | 1686 | 800 | 1285 | 475 | 62 | 200 | G3/4 | |||

| DNA-11LG | 7.5 | 109 | 1.64 | 57.9 | 11 | 15 | 1900 | 850 | 1450 | 600 | 63 | 250 | G3/4 | ||

| 8.5 | 123 | 1.63 | 57.6 | 11 | 15 | 1900 | 850 | 1450 | 600 | 63 | 250 | G3/4 | |||

| 10.5 | 152 | 1.47 | 51.9 | 11 | 15 | 1900 | 850 | 1450 | 600 | 63 | 250 | G3/4 | |||

| 13 | 189 | 1.21 | 42.7 | 11 | 15 | 1900 | 850 | 1450 | 600 | 63 | 250 | G3/4 | |||

| DNA-15LG | 7.5 | 109 | 2.10 | 74.2 | 15 | 20 | 2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | ||

| 8.5 | 123 | 2.00 | 70.6 | 15 | 20 | 2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | |||

| 10.5 | 152 | 1.80 | 63.6 | 15 | 20 | 2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | |||

| 13 | 189 | 1.60 | 56.5 | 15 | 20 | 2150 | 1000 | 1700 | 650 | 63 | 500 | G1 | |||

| DNA-18LG | 7.5 | 109 | 3.20 | 113.0 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | ||

| 8.5 | 123 | 3.00 | 105.9 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | |||

| 10.5 | 152 | 2.70 | 95.3 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | |||

| 13 | 189 | 2.30 | 81.2 | 18.5 | 25 | 2150 | 1000 | 1700 | 670 | 65 | 600 | G1 | |||

| DNA-22LG | 7.5 | 109 | 3.80 | 134.2 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | ||

| 8.5 | 123 | 3.60 | 127.1 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | |||

| 10.5 | 152 | 3.20 | 113.0 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | |||

| 13 | 189 | 2.80 | 98.9 | 22 | 30 | 2250 | 1200 | 1850 | 750 | 65 | 650 | G1-1/4 | |||

| DNA-30LG | 7.5 | 109 | 5.31 | 187.5 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | ||

| 8.5 | 123 | 5.00 | 176.6 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | |||

| 10.5 | 152 | 4.21 | 148.7 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | |||

| 13 | 189 | 3.75 | 132.4 | 30 | 40 | 2300 | 1200 | 1950 | 850 | 65 | 840 | G1-1/4 | |||

| DNA-37LG | 7.5 | 109 | 6.72 | 237.3 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | ||

| 8.5 | 123 | 6.25 | 220.7 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | |||

| 10.5 | 152 | 5.51 | 194.6 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | |||

| 13 | 189 | 4.43 | 156.4 | 37 | 50 | 2300 | 1200 | 1950 | 900 | 65 | 840 | G1-1/4 | |||

Typical Case:

Related Products:

Submit demand feedback online

You can fill out the following form, your contact information and product requirements submitted to us, we will contact you as soon as possible to resolve, thank you! In order to be able to contact you in a timely manner, please be sure to fill out your contact information and demand information.

contact us

company adddress: NO.89, Jinsuo road, Hi-tech zone, zhengzhou city , henan province

Zip code:450000

Hotline:13526805404

Service Hotline:13526805404

Email:Yonghanmachinery@126.com